- Choose Guangu Technology: Environmentally Friendly Polishing Machines Aren't Really Expensive

- A New Choice for Surface Treatment of Press-Fit Studs: Why Does Magnetic Polishing Achieve "Fast and High Quality"?

- Elastic R-shaped Pins and Magnetic Polishers: The Invisible Partner of Precision Manufacturing

- Innovative breakthrough of large metal polishing machine: magnetic polishing

- Magnetic polisher and plane polisher: Gemini of precision manufacturing

- Why magnetic polishers process metal surfaces so quickly

E-mail:zhihong@szguangu.com

Phone:18626103335

TEL:400-800-3945

Address:No. 333, Zixu Road, Xukou Town, Wuzhong District, Suzhou

Operating rules for magnetic metal polishing machine to deburr and deoxidize round gaskets of aluminum parts

Aluminum round gasket is often used in the production of mechanical seal parts such as container valves. It belongs to a kind of metal gasket. There are many manufacturers of metal gaskets. Manufacturers of mechanical seal parts such as container valves often consider the appearance of gaskets to achieve sandblasting effect when choosing round gaskets of aluminum parts. Therefore, after the processing of the round gasket of aluminum parts is completed, the surface often needs to be Deburring to oxidize the layer.

Deburring and oxidizing aluminum parts can be better used in the production of mechanical seal parts such as container valves. So how to deburr the aluminum round gasket to oxidize the layer? This is a common problem in many manufacturers of round gaskets for aluminum parts. Today, Guanguu Technology will introduce to you the operating procedures of Magnetic metal Polishing machine for deburring and deoxidizing aluminum round gaskets.

This is a round aluminum gasket. It can be seen that the surface problem of the round aluminum gasket is quite obvious. The color is black and dull locally, and it needs to be deburred and oxidized.

In order to remove the local black and dull color of the round gasket of the aluminum parts, then the Guan ancient magnetic metal polishing machine is used to deburr and remove the oxidation layer of the round gasket of the aluminum parts.

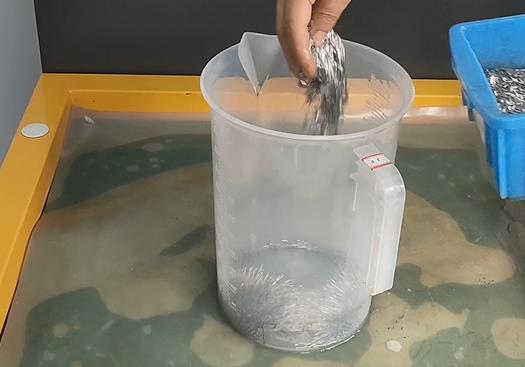

According to the size of the circular gasket of aluminum parts, select the appropriate magnetic needle, and use the magnetic needle to deburr the circular gasket of aluminum parts.

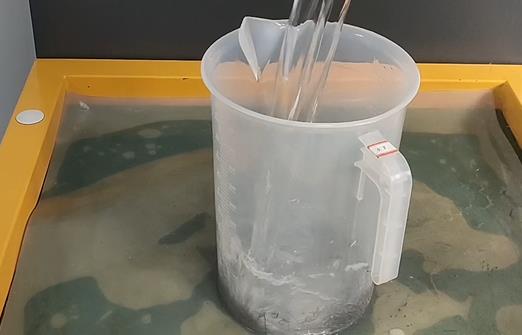

Pour clean water into the slot of the magnetic metal polishing machine, which can drown the round gasket of the aluminum parts:

Pour the polishing liquid to increase the metal luster on the surface of the round gasket of the aluminum parts:

Insert round gasket sample of aluminum parts:

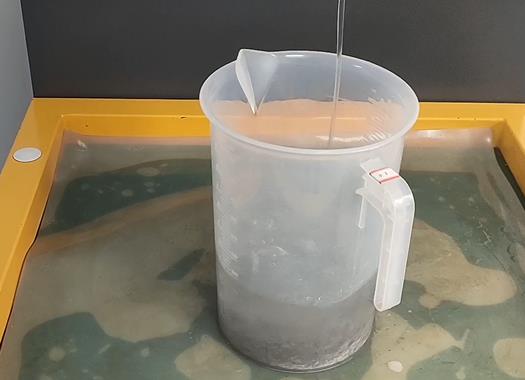

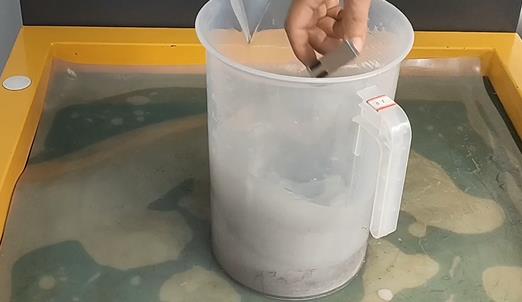

Deburring and oxidizing layer of round gasket for aluminum parts:

According to the size and material of the aluminum round gasket workpiece, wait for the corresponding time, after the completion of the deburring and oxidizing layer of the aluminum round gasket, remove the surface moisture of the aluminum round gasket. The following is the effect of the deburring and oxidizing layer of the aluminum round gasket, and the surface of the aluminum round gasket is smooth and metallic.

Local black and dull color on the round gasket of aluminum parts has been removed, and the appearance of the gasket surface has achieved the sandblasting effect, restoring the metal color of the round gasket of aluminum parts:

The round aluminum gasket is handled well, and the above is the operating procedure of the round aluminum gasket deburring and oxidizing layer. The local black and dull color of the workpiece needs to be removed. Welcome to consult the manufacturers who need polishing.

- Previous:Magnetic needle polishing machine for oil and air pump joint accessories cleaning and polishing manufacturers case

- Next:Magnetic needle polishing machine for aluminum furniture accessories polishing and deburring steps

-

2022-10-18Deburring of stainless steel stampings