- Choose Guangu Technology: Environmentally Friendly Polishing Machines Aren't Really Expensive

- A New Choice for Surface Treatment of Press-Fit Studs: Why Does Magnetic Polishing Achieve "Fast and High Quality"?

- Elastic R-shaped Pins and Magnetic Polishers: The Invisible Partner of Precision Manufacturing

- Innovative breakthrough of large metal polishing machine: magnetic polishing

- Magnetic polisher and plane polisher: Gemini of precision manufacturing

- Why magnetic polishers process metal surfaces so quickly

E-mail:zhihong@szguangu.com

Phone:18626103335

TEL:400-800-3945

Address:No. 333, Zixu Road, Xukou Town, Wuzhong District, Suzhou

Magnetic grinder for CNC machining of aluminum parts to remove residue and cut lines instructions

CNC machining Aluminum parts are often used in equipment manufacturing, it belongs to a kind of aluminum parts. There are many manufacturers of aluminum parts. Equipment manufacturers often need to consider the clean surface of aluminum parts without residue when using CNC machines to process aluminum parts. Therefore, after the completion of CNC machining of aluminum parts, the surface often needs to remove the residue to cut lines.

CNC machining of aluminum parts can be better used for equipment manufacturing. So how do CNC machining aluminum parts to remove residual and cut lines? This is a common problem of many CNC machining aluminum manufacturers. Today, Guanguu Technology will introduce to you the instructions of Magnetic Grinder for removing residual and cutting marks on aluminum parts processed by CNC machine.

This is a square shell shaped aluminum part. It can be seen that the surface problems of aluminum parts machined by CNC are quite obvious. There are knife marks and residue on the surface, which need to be removed.

In order to remove knife marks and residue on the surface of CNC machined aluminum parts, Guan Gu Magnetic Grinder is used to remove residue and knife marks on CNC machined aluminum parts:

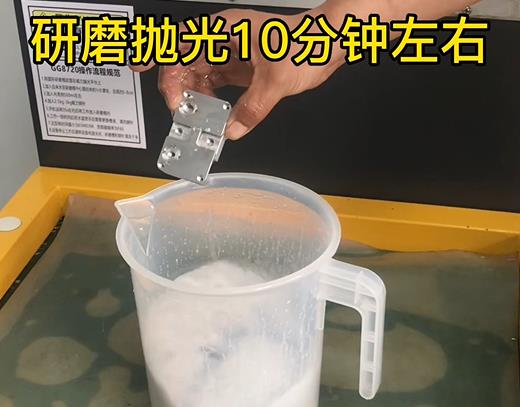

1. Pour water into the groove of the magnetic grinder, which can drown the CNC machining aluminum parts;

Two, according to the size of CNC machining aluminum parts to select the appropriate magnetic needle, using magnetic needle to CNC machining aluminum parts to remove residue and cut;

3. Pour the Polishing liquid to increase the metal luster on the surface of CNC machining aluminum parts;

Four, put into CNC machining aluminum samples:

5. Aluminum parts are being processed by CNC machine to remove residue and cut lines;

According to the size and material of the aluminum workpiece processed by CNC, wait for a period of time. After the aluminum workpiece processed by CNC is finished, the surface moisture of the aluminum part processed by CNC is removed. The following is the effect of the aluminum part processed by CNC, and the surface of the aluminum part processed by CNC is smooth and metallic.

Knife marks and residues on the surface of aluminum parts processed by CNC have been removed. The surface of aluminum parts is clean and without residue. The metal color of aluminum parts processed by CNC machines has been restored:

The square shell shaped aluminum parts have been processed, and the above is the instructions for the use of CNC machining aluminum parts to remove the residue and the knife lines. The manufacturers who need to remove the knife lines and the residue on the surface of the workpiece need to be polished are welcome to consult, and thank you for your support to the Guan ancient magnetic grinder.

- Previous:Operating rules for deoxidizing and deburring instrument brass accessories by environmental protection magnetic polishing machine

- Next:Magnetic metal polishing machine for zinc alloy flat key pin deburring cleaning and polishing process

-

2022-10-18Deburring of stainless steel stampings