- Choose Guangu Technology: Environmentally Friendly Polishing Machines Aren't Really Expensive

- A New Choice for Surface Treatment of Press-Fit Studs: Why Does Magnetic Polishing Achieve "Fast and High Quality"?

- Elastic R-shaped Pins and Magnetic Polishers: The Invisible Partner of Precision Manufacturing

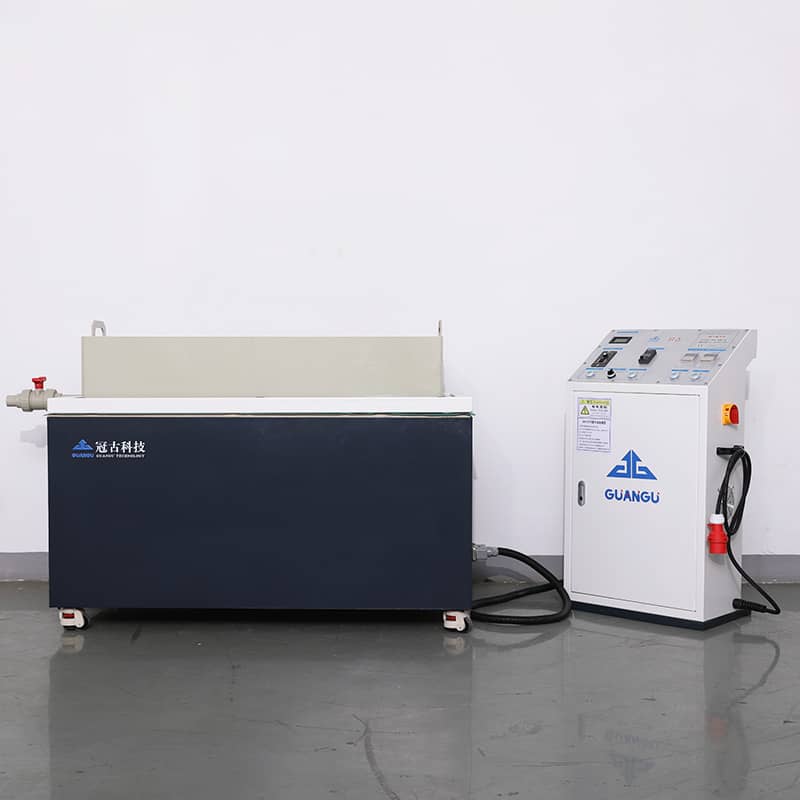

- Innovative breakthrough of large metal polishing machine: magnetic polishing

- Magnetic polisher and plane polisher: Gemini of precision manufacturing

- Why magnetic polishers process metal surfaces so quickly

E-mail:zhihong@szguangu.com

Phone:18626103335

TEL:400-800-3945

Address:No. 333, Zixu Road, Xukou Town, Wuzhong District, Suzhou

Application and advantages of magnetic polishing machine in surface treatment of water meter shell

As an important tool for water resource management in my country, the processing quality of its shell directly affects the performance and service life of the water meter. This article mainly introduces the Application and advantages of magnetic polishing machine in the processing of water meter shell, and provides a high-efficiency and environmentally friendly processing method for water meter manufacturing enterprises.

1. Introduction

With the rapid development of my country's economy, water resource management has received increasing attention. As an important equipment for measuring water volume, the market demand for water meter has increased year by year. As an important part of water meter, the appearance quality, corrosion resistance and precision of water meter shell have a great influence on the overall performance of water meter. Traditional Polishing methods have problems such as low efficiency and environmental pollution, while magnetic polishing machine, as a new type of polishing equipment, has gradually been widely used in the processing of water meter shell.

2. Working Principle of magnetic polishing machine

Magnetic polishing machine uses the effect of magnetic grinding media in magnetic field to grind and polish workpieces. Its main components include: magnetic field generator, grinding media, polishing liquid and control system. When working, the magnetic field generator generates a strong magnetic field, so that the grinding media (such as magnetic abrasives, grinding steel needles, etc.) are adsorbed on the surface of the workpiece, and the workpiece is ground and polished through the cooling and lubrication of the polishing liquid.

3. Application of magnetic polishing machine in water meter shell processing

Deburring: The water meter shell will produce certain burrs during the casting, stamping and other processing processes. The magnetic polishing machine can effectively remove these burrs and improve the finish of the shell.

Polishing: The magnetic polishing machine can finely polish the water meter shell to achieve a mirror effect on the surface finish and improve the appearance quality.

Rust removal: The water meter shell is prone to oxidation and rust during storage and transportation. The magnetic polishing machine can remove rust and restore the gloss of the shell.

Improve corrosion resistance: The water meter shell treated by the magnetic polishing machine has a reduced surface roughness and improved coating adhesion, thereby improving its corrosion resistance.

4. Advantages of magnetic polishing machine in water meter shell processing

High efficiency: The magnetic polishing machine has a fast processing speed and high efficiency, which greatly shortens the production cycle.

High precision: The magnetic polishing machine can achieve precision polishing to ensure the dimensional accuracy and shape accuracy of the water meter shell.

Environmental protection: The magnetic polishing machine uses water-based polishing liquid to reduce pollution to the environment.

Strong adaptability: The magnetic polishing machine is suitable for water meter shells of various materials, such as copper, Aluminum, stainless steel, etc.

Save manpower: The magnetic polishing machine has a high degree of automation and reduces labor costs.

V. Conclusion

The application of magnetic polishing machines in the processing of water meter shells has improved the processing quality of water meter shells and reduced production costs, which is in line with the development trend of green manufacturing and environmentally friendly production in my country. With the continuous maturity of magnetic polishing technology, it is believed that its application in the water meter manufacturing industry will be more extensive.

- Previous:Guan Gu Technology magnetic polishing machine: subvert the tradition, more durable, help manufacturing industry innovation and development

- Next:Application of magnetic suspension polishing process in the field of aluminum profile accessories

-

2022-10-18Deburring of stainless steel stampings